dump truck sectional valve

Get Latest Price| Payment Type: | L/C,T/T,D/P |

| Incoterm: | FOB,CFR,CIF,EXW,FCA,CPT,CIP |

| Transportation: | Ocean,Land,Air |

| Payment Type: | L/C,T/T,D/P |

| Incoterm: | FOB,CFR,CIF,EXW,FCA,CPT,CIP |

| Transportation: | Ocean,Land,Air |

Model No.: GKV50

Brand: GRH

Function: Flow Control

Installation: Threaded Cartridge

Drive: Hydraulic

Type: Directly Operated Type

Introduction of GKV50

Sectional Valves stated in other words Sectional Directional Control Valves are highly flexible and have various auxiliary valves such as anti-shock, anti-cavitation, electro hydraulic pilot operated unloader, hydraulic pilot unloader etc. Generally sectional valves have check valve for each work section are from 1 to 12 sections with open center, closed center hydraulic circuits. Various sections used together such as series, parallel or tandem circuit valve. Also sectional valves may have intermediate pump and tank sections. Between two sections it is possible to add pressure or flow compensator. As described above Sectional valves have various options when compared to Monoblock Valves. However there are some disadvantages of the sectional valves is lower working pressure when compared to monoblock valves. Sectional valves maximum working pressure should be 320 bar. Total sizes of the sectional valves are not as compact as monoblock valves, some space limited applications do not prefer big valves as sectional valves.

GKV 50 series sectional valves provide the following functions:

● Inlet module with two stage relief valve

● Inlet module with direct acting relief valve.

● A /B port with overload valve on main section V

● A port with overload valve on work section.

● B port with overload valve on work section.

● A port with dump valve

● B port with dump valve

● A/B port with a mechanical P.O check

● A port with a mechanical P.O check

● B port with a mechanical P.O check

● End section with oil return port.

● End section without oil return port.

● End section with power beyond port.

GKV50 Series sectional valve provides the following features:

● Cast iron body (inlet section, main section and end section).

● Spring cap, mechanical detent cap, as well as electoral or hydraulic pilot controlled module body are made by cast aluminum or die cast aluminum.

● Parallel circuit, each section have its own load check valve, each section has load option relief option and relief style options.

● Can be changed to series circuit.

● Provides dump valve options for each center valve.

● Provides different drive modules (Hydraulic remote, manually control, wire driving).

● Provides power beyond port.

● Can be modified to be a closed center valve.

● Provides mechanical detent

● Provides options for mechanically actuated P.O check valves to satisfied with the needs for tractors and mobile cranes

● Provides different spool function to be used for controlling double acting, single acting cylinders, Hydraulic Motors

● Provides floating function for spools

● Provides excellent flow characteristics small operating force

● Can be assembled with 1-8 main sections

Technical Data

Rated Flow Rate: 50L/min

Maximum Flow Rate: 60L/min

Minimum Flow Rate: 20L/min

Maximum Pressure at P port: 350bar

Maximum Pressure at A.B port: 350bar

Maximum Pressure at T port: 25bar

Internal Leakage(@70bar)A.B to T: 25-35cc/min

Internal Leakage(@70bar)A.B to T with P.O check: 2-5cc/min

Spool Stroke(1.2position): +7/-7mm

With flooating function(1.2position): +7/-7 -- 10mm

Solenoid can be either 12 VDC or 24 VDC, corresponding current is 0-1.5 or 0-0,75 Amp

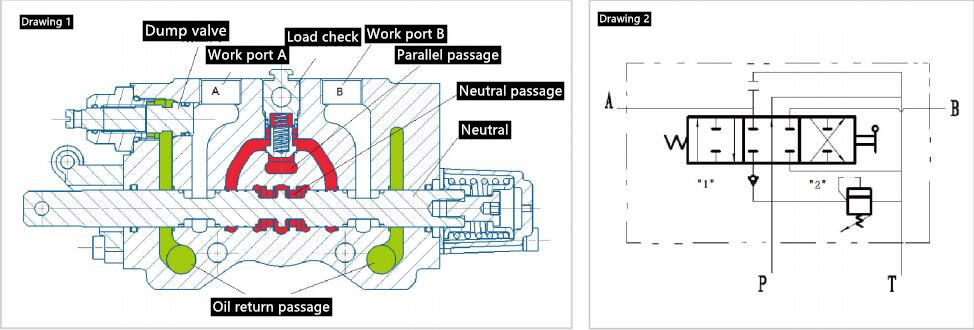

Basic Operation Principle

GKV50 series sectional valves is an open centered 3-position 4-way valve. When spool is in its neutral position, the flow from pump passes through the neutral passage to tank, with small pressure drop. When one of the spool is moved to 1 or 2 position, the neutral passage is blocked. The flow from pump can only pass the parallel passage to load check valve, then, passes through the bridge and spool opening to work port A or B.

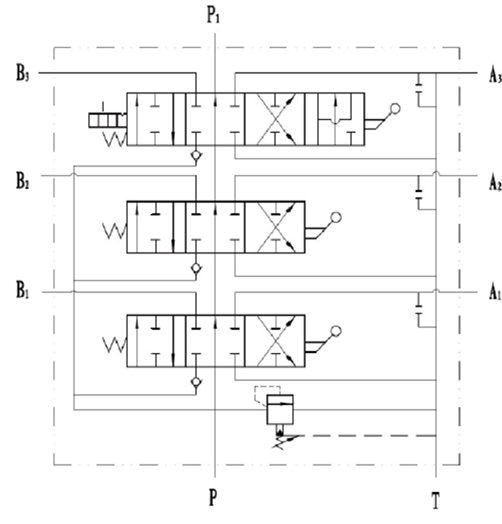

For multi-Section Valve, if one of the sections spool is in spool in or spool out position, then, there is no flow in its down stream sections neutral passage. Then main throttle occurs on the valve opening between bridge passage and spool. The operator can control more than one spools, but the magnitude of the flow rate for each controlled section depends on the magnitude of the load, as shown in drawing 3.

When power beyond function is selected as shown in drawing 4, when all spools are in neutral position, the flow from inlet passes neutral passage to power beyond port to provide source of the flow to other auxiliary functions.

Application Example

3 Section Stack Valve

Munual Control 3 Section Valve

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.